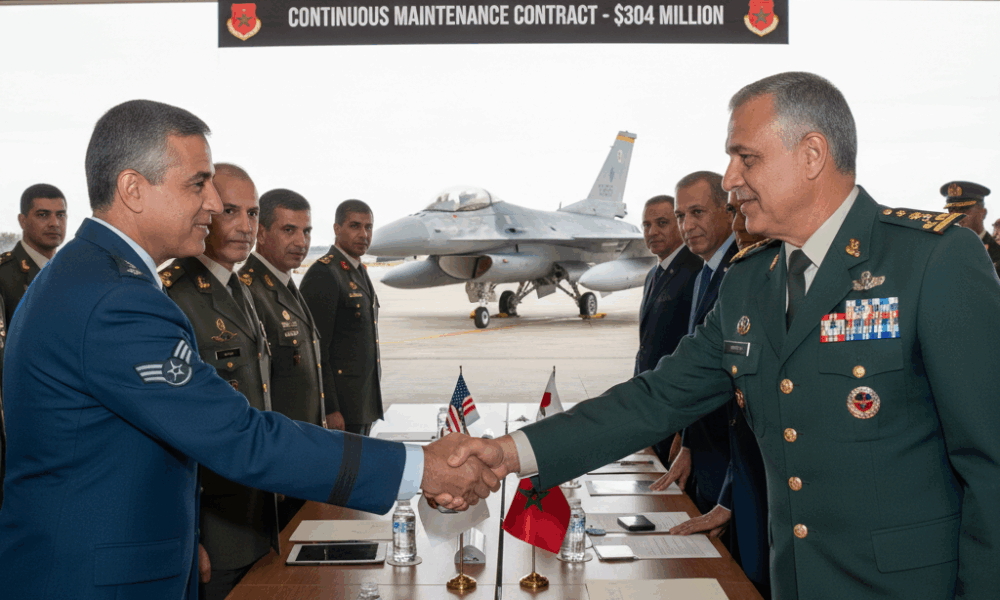

Why the United States Entrusts 304 Million Dollars to Morocco for the Continued Maintenance of F-16s

The contract of 303.6 to 304 million dollars awarded by the United States to Northrop Grumman for the sustainable support of the radars of F-16 aircraft incorporates Morocco as a key partner. This multi-year package, structured as a “firm-fixed-price, IDIQ,” ensures maintenance service and “repair-and-return” until November 2030 for critical components of the AN/APG-83 AESA radars. In the ecosystem of defense and logistical support, this choice consolidates the Kingdom’s place in the global F-16 support chains while offering strategic visibility to local stakeholders.

The program is anchored to the Pentagon’s Cyber Resiliency Program, which aims to protect aeronautical systems against digital threats. The challenge is not limited to spare parts: it covers test protocols, repair traceability, software integrity, and operational availability. For the Moroccan economy, the interest is twofold: acquisition of know-how and inscription in a long-term technical partnership with the American industry.

Morocco is among eight international partners at the core of the main lot, alongside Bahrain, Bulgaria, Greece, South Korea, Slovakia, Taiwan, and Jordan. Beyond that, an extended radar support perimeter includes Pakistan, Iraq, Oman, Singapore, Indonesia, Chile, and Argentina. For a job market in search of skilled trades, these networks multiply opportunities for secondary contracts, technology transfers, and professional mobility.

This trajectory builds on previous decisions: Moroccan order of 24 F-16V “Viper”, upgrade of the existing fleet to the same configuration, and American authorization of technology transfers exceeding 50 million dollars for local component production. Added to this are infrastructure initiatives, such as the Maintenance Aero Maroc (MAM) site: an 8,000 m² hangar under construction in Benslimane, operational by end of 2026.

Strategic Scope and Operational Expectations

In practice, the contract covers the repair of radar modules, software updates, calibration, quality assurance, and reverse logistics. Specifically, this means controlled timelines, capped costs, and better-integrated predictive maintenance. For air forces, availability increases, downtime cycles decrease, and mission planning gains reliability.

For Moroccan suppliers, strict standards (documentation, traceability, data security) become the norm. As a result, a credible positioning emerges to respond to other civil and military aeronautical markets, on the continent and beyond.

- ✅ 304 million dollars dedicated to supporting F-16 radars 🛩️

- 🔒 Integration into the Cyber Resiliency Program to secure digital systems

- 🌍 Morocco as a member of the central group alongside European, Asian, and Middle Eastern partners

- 🛠️ Spillover effect for advanced maintenance, logistics, and quality assurance

- 🚀 Vector of skilled jobs and skill upgrading in aerospace

| Countries concerned 🌐 | Role in the contract 🧭 | Deadline ⏳ | Key elements 🔧 |

|---|---|---|---|

| Morocco | Regional support hub F-16 | Nov. 2030 | APG-83 AESA, repair-and-return ✈️ |

| Bahrain, Jordan | MENA partners | 2025-2030 | Operational availability 📈 |

| Bulgaria, Greece, Slovakia | NATO interoperability 🇪🇺 | 2025-2030 | Quality standards 🔍 |

| South Korea, Taiwan | Industrial expertise | 2025-2030 | Volumes and cadence ⚙️ |

This technical and contractual foundation opens the way to employment impact, a topic addressed in the next section.

Employment and Skills: the Impact of the F-16 Maintenance Contract on the Moroccan Labor Market

The American-Moroccan agreement creates increased demand for technical, logistical, and digital profiles. The employment pools of Nouaceur, Benslimane, Kénitra, and Rabat should concentrate recruitments, linked with existing aeronautical clusters. Emerging trades revolve around avionics maintenance, onboard cybersecurity, test engineering, and reliability analytics.

A typical career path illustrates this dynamic: Salma, an electronics graduate, joins a team dedicated to AN/APG-83. Her daily routine combines diagnostics, schematic reading, RF test benches, secure software updates, and quality reporting. Over months, she obtains certifications, then mentors junior technicians, improving compliant return rates. This type of trajectory promotes equal opportunity and attracts Moroccan talents trained locally or returning from abroad.

Companies anticipate transversal skill needs: configuration management, critical supply chain, operational safety, and document compliance. HR prioritizes modular training, certification programs, and bridges between workshops, engineering, and customer support. Salaries follow the technicality of positions, with bonuses linked to certifications and deadline adherence.

Jobs, Volumes, and Career Pathways

The economic fabric values experience and certifications. Young graduates are integrated through grad programs, while experienced professionals bring maturity and best practices. Pathways to civil aeronautics exist, notably in commercial avionics and MRO.

- 🧑🔧 Avionics Technician: calibration, RF tests, documentation 📘

- 🖥️ Embedded Cybersecurity Engineer: hardening, audits 🔐

- 📦 Critical Parts Logistician: traceability, stocks ⛓️

- 📊 Reliability Data Analyst: failure trends, forecasting 📈

- 🧪 Test Bench Specialist: preventive maintenance, tooling ⚙️

| Job Family 👔 | Estimated Staff 2025-2027 👥 | Indicative Salary 💶 | Key Certification 🏅 |

|---|---|---|---|

| F-16 Avionics | 200–350 | 8,000–14,000 MAD/month | IPC/WHMA-A-620, ESD 🧤 |

| Systems Cybersecurity | 60–100 | 12,000–20,000 MAD/month | Security+, CISSP 🔒 |

| Critical Logistics | 80–120 | 7,000–11,000 MAD/month | APICS, IATA 📦 |

| Quality & Compliance | 50–90 | 9,000–15,000 MAD/month | AS/EN 9100 🔍 |

The prospects are all the stronger as the schedule extends to 2030. To capitalize, the HR ecosystem will need to streamline technical English, quality culture, and document rigor, while valuing coordination soft skills.

The rise of these professions requires alliances between schools and industry players, addressed in the next section around the supply chain.

Local Supply Chain and Co-Industrialization: Capturing the Value of the United States–Morocco Partnership

The value of a multi-million dollar contract is played out as much in workshops as in the supply chain. Morocco has a pool of equipment suppliers, SMEs, and mid-sized companies able to produce harnesses, boards, lightweight structures, tooling, and test software. The goal is not just assembly, but co-engineering and documentation that meet international standards.

The MAM project in Benslimane acts as a catalyst. Around an 8,000 m² hangar, Moroccan, Belgian, and American partners structure subcontracting flows: modular repair, rework, calibration, packaging, export compliance. Contractual deadlines impose tight cycle times, hence the importance of digital solutions for traceability and fine scheduling.

Technical transfers already validated by Washington (> 50 million dollars) provide the basis to produce Viper components locally, reduce import dependence, and stabilize costs. Implicitly, the Kingdom positions itself as a maintenance and distribution platform for Africa and part of the Middle East, with a spillover effect on precision metallurgy, electronics, logistics, and digital services.

Market Access, Quality, and Financing

For SMEs, three factors dominate: compliance (AS/EN 9100, ITAR/EAR), digitization (MES, PLM), and financing (equipment leasing, advance payments). Moroccan banks are beginning to offer solutions dedicated to aeronautics, while sector funds support investments in tooling and certifications. American contractors demand full visibility on 2nd/3rd tier suppliers.

- 📑 Compliance with aeronautical and export ITAR/EAR standards ✅

- 🧭 Digital traceability and production twins 🛰️

- 💶 Leasing for test benches, NDT, metrology 💡

- 🤝 Partnerships with technical centers and universities 🎓

- 🚚 Optimized international logistics (incoterms, transit times) ⏱️

| Supplier Segment 🏭 | Product/Service 🧰 | Key Requirement 📏 | Opportunity 2025-2030 🚀 |

|---|---|---|---|

| Electronics | Boards, harnesses, connectors | AS/EN 9100, ESD, ICT tests | Radar module integration 🛩️ |

| Precision Mechanics | Supports, casings, machining | GD&T, NDT, traceability | Regular volumes, export 🌍 |

| Software & Testing | Benches, scripts, PLM/MES | Security, validation, audits | Predictive maintenance 📊 |

| Logistics | Repair-and-return | Incoterms, TAT, packaging | Regional hub ✈️ |

By consolidating this chain, Morocco diversifies its economy and increases the share of local added value. The next focus is on skills and cyber-resilience, the cornerstone of the American program.

Training, Certification, and Cyber-Resilience of F-16s: 2025-2030 Roadmap

Integration into the American cyber-resilience program implies a qualitative leap in skills. Curricula must cover RF electronics, real-time systems, cybersecurity, aeronautical standards, and document management. A competency block approach, co-built with industry players, accelerates employability and ensures operational reliability.

Moroccan institutions such as IMA in Nouaceur, OFPPT, Mohammed VI Polytechnic University, ENSA, and ENIM can structure 6- to 18-month programs: RF modules, test protocols, cyber hygiene, technical English, safety culture, and audits. International certifications (EN/AS 9100, IPC, CompTIA Security+) become passports to work on F-16 chains.

Cyber-resilience is embodied by workstation hardening, network segmentation, signed updates, SOC supervision, vulnerability hunting, and attack simulation. Workshops must integrate digital safes for cryptographic keys, removable media control procedures, and periodic access reviews. Each prevented incident protects the airplanes’ availability and the partnership credibility with the United States.

Learning Paths and Maturity Growth

A clear progression model reassures candidates and employers: avionics fundamentals, bench qualification, RF/cyber specialization, then quality responsibilities or supervision. Internships facilitate the appropriation of professional gestures. Training organizations can co-invest in mini test benches, in partnership with SMEs, to multiply real situations.

- 🎓 Bootcamps 12–16 weeks in avionics and safety

- 🧪 Labs RF and cybersecurity with F-16 use cases

- 📚 Intensive technical English and document writing

- 🛡️ Cyber drills: phishing, EDR, incident response

- 🔁 Internships in MRO and quality workshops

| Module 📘 | Duration ⏱️ | Certification 🏅 | Expected Outcome ✅ |

|---|---|---|---|

| F-16 Avionics (APG-83) | 4–6 months | IPC, EN/AS 9100 | Testing, calibration, traceability 📈 |

| Embedded Cybersecurity | 3–4 months | Security+, CEH | Hardening, audits 🔒 |

| Quality & Documentation | 2–3 months | 9100 Lead Auditor | Audits, non-conformities 🔍 |

| Critical Supply Chain | 2–3 months | APICS | Reduced TAT, zero breaks 🚚 |

With these building blocks, the ramp-up toward 2030 remains realistic and sustainable, while protecting digital assets and industrial reputation.

Strategic Perspective: from F-16s to F-35s, Scenarios for the Moroccan Defense Economy

Current cooperation serves as a springboard toward more advanced capabilities. A project under study mentions the potential acquisition of 32 F-35s, the finalization of which depends on sensitive approvals, notably Israeli. The multi-decade envelope, estimated up to 17 billion dollars over 45 years (aircraft, training, maintenance, and support), would transform the industrial base and skills map. The decision must balance technological sovereignty, budgetary sustainability, and socio-economic fallout.

In the regional environment, Algeria turns to Su-57 and Su-35, while Egypt explores Chinese aircraft. Morocco, anchored in a historical partnership with the United States, consolidates a positioning of Western interoperability. Missile, sensor, and training programs align with a logic of technological superiority and availability.

Three scenarios shape the thinking: continue optimizing F-16 with industrial footprint growth; opt for an F-16/F-35 mixed step; consider a faster switch to 5th generation. Each implies HR organizations, investment envelopes, transfer schedules, and different risks. Common points: advanced training, cyber, resilient supply chain, and capacity to maintain high availability rates.

Economic Trade-offs and Multiplier Effects

Defense spending can generate an industrial multiplier if local benefits are captured: subcontracting contracts, export of MRO services, technological diffusion toward civil aeronautics and space. Already dynamic regions (Casablanca-Settat, Rabat-Salé-Kénitra) can attract satellite hubs to Béni Mellal-Khénifra or Fès-Meknès through bridging schools and specialized industrial parks.

- 🧭 Scenario 1: Optimized F-16s, enlarged industrial footprint

- 🛫 Scenario 2: F-16/F-35 mix, gradual rise to 5th gen

- 🚀 Scenario 3: Accelerated 5th gen, strong budgetary requirement

- 🛡️ Key criterion: operational availability and cyber-resilience

- 🤝 Condition: offset contracts and local co-engineering

| Scenario 🧭 | Estimated CAPEX 💰 | Direct/Indirect Jobs 👥 | Main Risk ⚠️ |

|---|---|---|---|

| F-16+ | Moderate | 1,500 / 4,000 | Tech dependence 🌐 |

| F-16/F-35 Mix | High | 2,500 / 6,000 | Logistics complexity 🔄 |

| Fast F-35 | Very high | 3,500 / 8,000 | Skill absorption ⏳ |

Regardless of the scenario, the winning industrial footprint will be the one combining quality rigor, trained talents, and a secure digital ecosystem. The 304 million dollar contract is, in this respect, a measurable acceleration ramp.

Governance, Financing, and Inclusion: Turning a Contract into a Long-Term Opportunity

Success depends on clear public-private governance: industrial priorities, milestones, indicators, and transparency. A steering committee can aggregate the relevant ministries, armed forces, clusters, and training institutions. Indicators track jobs created, local value share, certifications obtained, TAT (Turnaround Time), and cyber compliance.

Financing combines defense budget, incentives for productive investment, subsidized loans, and guarantee instruments. Local banks, reassured by visibility until 2030, can offer dedicated lines for test machines, software, metrology, and certified training. American industrialists involved in the partnership can co-finance test labs to secure schedules.

Inclusion imposes itself as a lever for performance. Objectives for gender balance, integration of young graduates, and requalifying experienced technicians strengthen absorption capacity. Targeted scholarship and industrial chair schemes facilitate certification access. Non-metropolitan regions can position themselves via training branches and satellite workshops, to avoid excessive opportunity concentration.

Indicators, Transparency, and Territorial Anchorage

Trust is built through measurement. Reporting progress, avoided incidents, introduced innovations, and volumes handled adds credibility to the ecosystem. Aggregated, anonymized, and periodically published data stimulate emulation between sites and continuous improvement. Local authorities’ involvement supports company hosting and talent mobility.

- 📌 KPI: net jobs, local share, TAT, compliance rate ✅

- 💳 Financing: leasing, green loans, public guarantees 💼

- 🌱 ESG: workshop energy efficiency, recycling ♻️

- 👩🔧 Inclusion: gender balance, youth integration, reskilling 🔁

- 🛰️ Data: shared dashboards, regular audits 📊

| Lever 🎯 | Priority Action 🛠️ | Expected Impact 📈 | Deadline ⏳ |

|---|---|---|---|

| Governance | Multi-stakeholder steering committee | Fast decisions, alignment 🤝 | Immediate |

| Financing | Dedicated equipment/testing lines | Increased capacity, deadlines met ⏱️ | 2025–2027 |

| Skills | Targeted certification programs | Employability, quality 🔍 | 2025–2030 |

| Transparency | Public quarterly reporting | Trust, attractiveness 🌟 | Continuous |

With demanding and inclusive governance, Morocco transforms a military cooperation into a sustainable engine of competitiveness, jobs, and innovation.

{“@context”:”https://schema.org”,”@type”:”FAQPage”,”mainEntity”:[{“@type”:”Question”,”name”:”What exactly does the 304 million dollar contract related to the F-16 cover?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”It is an American FMS agreement, approximately 303.6 to 304 million dollars, for sustainable maintenance and repair of the radar components of the F-16 (AN/APG-83 AESA), with repair-and-return, calibration, and software update services until November 2030.”}},{“@type”:”Question”,”name”:”Why was Morocco selected by the United States?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Morocco modernized its F-16 fleet to the Viper standard, invested in infrastructure (e.g., an 8,000 m² hangar in Benslimane), and benefits from recent technology transfers. Its aeronautical ecosystem, stability, and talents make it a credible and sustainable partner.”}},{“@type”:”Question”,”name”:”What are the employment benefits for Morocco?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Technical and digital job creation is expected: avionics, cybersecurity, critical logistics, quality. The regions of Nouaceur, Benslimane, and Rabat-Kénitra will concentrate needs, with salaries rising according to certifications.”}},{“@type”:”Question”,”name”:”Does the contract include a cybersecurity component?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Yes. It is part of the Pentagon’s Cyber Resiliency Program, with system hardening, audit procedures, and secure updates to guarantee aircraft availability and integrity.”}},{“@type”:”Question”,”name”:”What is the link to a possible purchase of F-35s?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Strengthening F-16 capabilities prepares scenarios for evolving towards the 5th generation. An option for 32 F-35s, potentially reaching 17 billion dollars over 45 years, remains conditioned on specific authorizations and budgetary sustainability.”}}]}What exactly does the 304 million dollar contract related to the F-16 cover?

It is an American FMS agreement, approximately 303.6 to 304 million dollars, for sustainable maintenance and repair of the radar components of the F-16 (AN/APG-83 AESA), with repair-and-return, calibration, and software update services until November 2030.

Why was Morocco selected by the United States?

Morocco modernized its F-16 fleet to the Viper standard, invested in infrastructure (e.g., an 8,000 m² hangar in Benslimane), and benefits from recent technology transfers. Its aeronautical ecosystem, stability, and talents make it a credible and sustainable partner.

What are the employment benefits for Morocco?

Technical and digital job creation is expected: avionics, cybersecurity, critical logistics, quality. The regions of Nouaceur, Benslimane, and Rabat-Kénitra will concentrate needs, with salaries rising according to certifications.

Does the contract include a cybersecurity component?

Yes. It is part of the Pentagon’s Cyber Resiliency Program, with system hardening, audit procedures, and secure updates to guarantee aircraft availability and integrity.

What is the link to a possible purchase of F-35s?

Strengthening F-16 capabilities prepares scenarios for evolving towards the 5th generation. An option for 32 F-35s, potentially reaching 17 billion dollars over 45 years, remains conditioned on specific authorizations and budgetary sustainability.

Comments are closed