BlueBird unveils its first factory in North Africa in Morocco: employment, value chain, and industrial upgrade

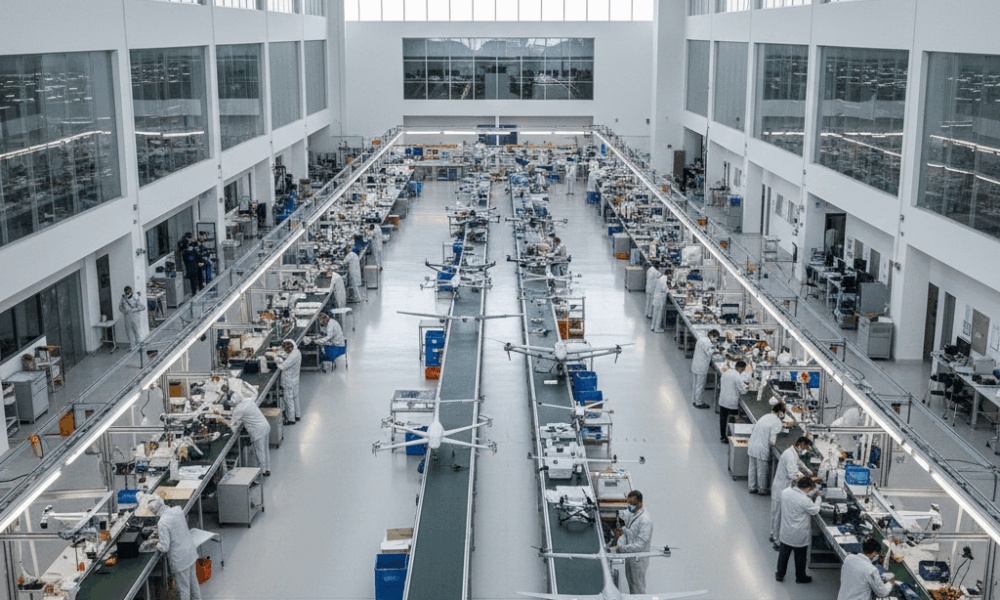

Morocco takes a strategic step with the inauguration of a drone production factory in partnership with an Israeli company, BlueBird Aero Systems. Located in Benslimane, east of Casablanca, the infrastructure is announced as one of the most modern on the continent. The site targets the assembly and integration of tactical platforms, notably unidirectional systems of the SpyX type, with a clear objective: to develop a strong and competitive national aerospace industry. This momentum opens a new horizon for qualified industrial employment, local subcontracting, and technological innovation applied to dual-use applications.

The operational priority is twofold. On one side, securing the supply of critical components (avionics, payloads, data links). On the other, transferring know-how to Moroccan teams, already trained in Israel for the startup phase. In 2025, the first pre-series batches will come off the lines, with a progressive ramp-up to full industrialization. Benslimane’s role fits into a broader vision: making the Kingdom a regional aerospace integration hub capable of attracting European, African, and Middle Eastern partners sensitive to the stability and quality of Moroccan infrastructures.

The employment impact is tangible. Recruitment covers machining profiles, electromechanical integration, flight testing, embedded cybersecurity, and industrial quality. Additionally, supporting trades include purchasing, supply chain, methods, HSE, and predictive maintenance. The indirect benefits flow to regional SMEs in composite materials, connectors, energy, logistics, and services. The consolidation of industrial zones around Benslimane also depends on effective urban planning and integrated development. In this regard, land development actors play a useful role in strengthening territorial ecosystems, as illustrated by this analysis on urban planning and the structuring of activity zones.

Priority jobs and skills in the new industrial chain

The HR dynamics combine local recruitment, requalification of technicians from the automotive and aerospace sectors, and integration of young graduates oriented toward embedded systems. The paths include intensive modules on quality, non-conformance management, and test & validation. To accelerate, several Moroccan engineering schools have adjusted their teaching units towards UAV architectures, inertial navigation, and radio link protection.

- 🚀 Avionics integrators: sensor assembly, calibrations, functional tests.

- 🛠️ Composite technicians: draping, infusion, ultrasonic testing.

- 📡 Data link specialists: radio frequency, anti-jamming, cryptography.

- 🔎 Quality & compliance: aerospace standards, parts traceability, audits.

- 🌱 HSE & energy: energy efficiency, workstation safety, circular economy.

In a ramp-up scenario over 24 to 36 months, projections mention several hundred direct jobs and a multiple of indirect jobs. The symmetry with existing automotive skills (stamping, electronics, lean) facilitates the learning curve. Public support mechanisms for training and R&D are a decisive lever, as is the quality of industrial land and logistics connections.

| Key function ✅ | Target volume (phase 1) 👥 | Critical skills 🧠 | 24-month evolution 📈 |

|---|---|---|---|

| UAV integration | 80-120 | Assembly, tests, ESD ⚡ | +50% via partial automation |

| Quality & testing | 40-60 | Aerospace standards, DO-178/DO-254 📋 | +30% with advanced test benches |

| Supply chain | 25-35 | Strategic purchasing, traceability 📦 | +20% via local suppliers |

| Maintenance & HSE | 20-30 | Preventive, safety, energy 🔧 | Stabilization through digitalization |

The cornerstone remains the trust of the clients in Morocco’s ability to deliver on time and in quality. This first industrial milestone positions the country as a serious player in the regional UAV chain, with a competitive and sustainable value proposition.

Technology transfer and technological innovation: from training to system integration

The heart of the partnership relies on a structured and measurable technology transfer. The Moroccan teams trained by the Israeli company are already operational on final assembly and functional testing. The goal for 2025-2026 is to progressively localize the manufacturing of sub-assemblies: composite fuselages, electronic bays, harnessing, and certain payloads. Technical milestones are tied to maturity indicators (TRL) and cross audits to evaluate process reproducibility.

This skill upgrade is accompanied by investments in test benches, metrology, and precision tooling. Aerospace industry standards (configuration management, documentation, design reviews) are deployed to embed quality in the workshop culture. The use of digital twins on the assembly line allows simulation of industrialization scenarios, optimization of cycle times, and defect prevention. The logic is simple: create a digital continuum, from design to acceptance, to secure production.

Bridges are built with Moroccan universities to foster applied research topics: resilient navigation algorithms, bio-sourced composite materials, and post-quantum cryptography protocols adapted to data links. Local innovation contests are mobilized to bring out startups able to contribute value bricks, from automated software testing to embedded imaging. These initiatives strengthen technological innovation while creating high-level employment opportunities.

Technical milestones and localization trajectory

The industrial roadmap sets three waves. The first covers final assembly and software integration, with a partial localization rate. The second adds the manufacturing of substructures and harness industrialization. The third, more ambitious, aims to co-develop payloads, integrate cybersecurity by design, and export sub-assemblies made in Morocco.

- 🧩 Phase 1 – Integration: test benches, procedures, reinforced quality control.

- 🏗️ Phase 2 – Manufacturing: composites, harnessing, technical painting.

- 🛰️ Phase 3 – Co-development: payloads, embedded AI, export.

| Module 🧱 | Current TRL 🔬 | Target localization 🇲🇦 | Key benefit 🎯 |

|---|---|---|---|

| Composite fuselage | TRL 8 | 50% in 18 months | Weight reduction, controlled costs 💡 |

| Avionics | TRL 9 | Local assembly | Responsiveness, traceability 📍 |

| Data link | TRL 8 | Local integration | Resilience, security 🔐 |

| Payloads | TRL 7-8 | Co-dev 24-36 months | Differentiation, export 🚀 |

The coordination between factory, campus, and subcontractor ecosystem forms the backbone of success. The quality of zone developments and logistical access conditions this trajectory, hence the interest in resources like this note on industrial zone planning to support UAV ecosystems.

Relying on international standards, the Moroccan sector consolidates its credibility and prepares to address broader markets within the framework of international cooperation.

Territorial benefits and local SMEs: Benslimane, future defense industry hub

The Benslimane site is seen as a pivot of economic and industrial development. Benefits are not limited to direct employment: they irrigate services, logistics, subcontracting, energy, and maintenance. Local authorities and investment agencies target a cluster effect, articulated with other industrial projects along the Casablanca–Benslimane–Rabat axis. This network strengthens attractiveness for international investors, while consolidating opportunities for Moroccan SMEs aiming to move upmarket.

Two structuring projects stand out. The first concerns infrastructures: industrial roads, reliable electrical networks, local data centers, and test platforms. The second touches urban planning: housing for managers and technicians, daily mobility, health services, and continuing education. A resilient ecosystem is born at the junction of these dimensions, as illustrated by the importance given to productive urbanism projects and planning approaches. In this regard, reflection on links between urban planning and industrial performance remains key to avoiding bottlenecks.

The local fabric is structured around specialized workshops: aerospace wiring, precision mechanics, surface treatments, technical packaging, and composite recycling. Young graduates find concrete bridges through work-study programs, while experienced automotive employees retrain for integration positions. The administration encourages simplified procedures to gain speed: one-stop shop, investment incentives, and co-financed training mechanisms.

SMEs and startups in the UAV chain: where to position?

For SME leaders, the central question is: which niche to choose, and what standard to target to become tier 2 or 3 supplier? The answer involves documented quality, traceability, and the ability to deliver at the right cost/quality/delivery. Major client tenders require full visibility on compliance as well as a business continuity plan.

- 🏭 Composites: structural parts, nacelles, radomes.

- 🔌 Wiring: complex harnesses, automated electrical tests.

- 🧪 Treatments: anodizing, technical painting, NDT control.

- ♻️ Recycling: recovery of composite scraps.

- 🚚 Specialized logistics: ESD packaging, secure transport.

| SME segment 🧭 | Key requirement 🔧 | Quality indicator 📊 | Local opportunity 🌍 |

|---|---|---|---|

| Composites | NDT control 🛰️ | Defects < 1% ✅ | Strong demand for shells 🚀 |

| Harnesses | Electrical tests ⚡ | 100% coverage 🧪 | Local integration increasing 📈 |

| Treatments | Process certification 📜 | PPM < 500 🔍 | Regional value chain 🤝 |

| Logistics | ESD & traceability 🧲 | 100% package scanning 📦 | Stabilized export flows 🚢 |

The momentum will be smoother as welcoming zones are carefully planned. Urban planning tools, detailed by experts as in this article on infrastructure–industry coordination, align land, mobility, and services. The expected result: sustainable competitiveness and strengthened attractiveness for complementary investments.

Regulation, economic diplomacy, and international cooperation: securing export and compliance

In a context of strengthened international cooperation, the opening of a joint factory between Morocco and an Israeli company requires rigorous governance of compliance. Component, software, and technical data flows are subject to strict export regulations, both Moroccan and foreign. Contracts govern the end-use, non-proliferation, and protection of sensitive technologies. Compliance is not just an obligation: it is a competitive advantage that reassures clients and partner authorities.

The regional context has evolved: standardization agreements have increased exchanges, and the international press notes the growth of technological exports to signatory countries. For Morocco, stability, quality procedures, and embedding in multilateral partnerships create a favorable framework. In 2025, compliance audits align with best practices: visitor control, digital access management, data encryption, and traceability of dual-use components.

Industrial players deploy ethics committees and vigilance cells to anticipate risks: misuse diversion, cybersecurity, supplier dependency. Contractual resilience includes continuity clauses, logistical backup plans, and redundancy of certain critical equipment. This robust framework strengthens the legitimacy of the Moroccan sector, both with public partners and private clients.

Compliance checklist for operators and subcontractors

Compliance requires documented and verifiable routines. Chain SMEs must integrate these requirements early to access markets. The one-stop shop and technical guides promote rapid adoption of good practices.

- 🔐 Access management: badge, zoning, workstation encryption.

- 📜 Contracts & licenses: end-use clauses, export control.

- 🧾 Traceability: serialization, batch history, audits.

- 🧯 HSE & safety: battery storage, ESD risks, evacuation plans.

- 🧪 Quality: FMEA, SPC, non-conformity management.

| Domain 🛡️ | Key requirement ✅ | Expected evidence 📂 | Frequency ⏱️ |

|---|---|---|---|

| Physical security | Zoning & badging | Access log 🧾 | Daily |

| Cybersecurity | Encryption, MFA | Scan report 🔍 | Weekly |

| Quality | SPC, FMEA | Dashboards 📊 | Monthly |

| Export compliance | Valid licenses | License files 📑 | Per batch |

The territorial framework also matters. Local resources facilitate alignment between urban planning, security, and industry, as highlighted in this focus on activity zone orchestration. From location to export, coherence between public policy and industrial requirements remains a key success factor.

For Moroccan companies, this discipline is a passport to access global value chains. It makes the sector credible to partners seeking reliable, compliant, and sustainable sites.

Jobs of the future and training: accelerating the upskilling of Moroccan talents

The commissioning of the factory creates an impetus for technical and digital trades. Needs cover integration, testing, industrial data, and cybersecurity. Training organizations adapt their programs: UAV modules, configuration management, environmental testing, and safety of operations. Intensive bootcamps align operational skills with workshop requirements. Concrete stories emerge, like Yasmine, a technician from an ISET, who underwent accelerated test & validation training and is now a reference on avionics test benches.

Career paths are expanding. A composite technician can evolve towards workshop manager; an avionics integrator towards methods engineer; an RF specialist towards data link manager. Soft skills complement the range: problem-solving, technical communication, and quality culture. Companies value certifications and versatility, especially to ensure team flexibility during peak periods.

Certifying pathways and sectoral bridges

The sector builds upon the achievements of the automotive and civil aerospace industries in Morocco. Bridges reduce training time and increase employability. Partnerships are formed with schools and competence centers to offer short courses and targeted tutored projects based on workshop needs.

- 🎓 Quality certifications: mastering audits and SPC indicators.

- 🧰 Workshop skills: ESD, wiring, visual & NDT control.

- 💻 Digital factory: MES, traceability, data visualization.

- 🛰️ Embedded systems: sensors, GNSS, secure communications.

- 🌍 Technical English: documentation, international project meetings.

| Profile 🎯 | Key certification 🏅 | Career development 📈 | Cross-cutting skill 🧠 |

|---|---|---|---|

| Composite technician | NDT control 🔎 | Team leader ▶️ workshop manager | Lean & 5S 🧹 |

| Avionics integrator | ESD/IPC-610 ⚡ | Methods engineer ▶️ quality | FMEA product 📋 |

| RF specialist | Radio & encryption 🔐 | Data link manager | Project management 📆 |

| Quality engineer | SPC & audits 🧪 | Quality manager ▶️ operational excellence | Technical communication 🗣️ |

Territorial competitiveness also depends on living conditions: housing, mobility, services. Integrated urban reflection fosters talent attraction, as highlighted in this analysis on the link between urbanism and industrial competitiveness. By promoting inclusion, diversity, and equal opportunities, the sector strengthens its ability to retain skills.

The message to young people and professionals in retraining is clear: UAV-related trades offer concrete prospects, provided investment in quality, digital, and technical English.

Macroeconomic effects and diversification: how the UAV sector strengthens economic development

Beyond the Benslimane site, the UAV sector acts as a catalyst for economic development. Productive investments stimulate demand for intermediate goods, increase potential exports, and spread operational excellence practices within Moroccan value chains. Alignment between industrial policy, training, and territorial development increases resilience to exogenous shocks, while strengthening technological sovereignty.

Dual-use applications create bridges with civil security, precision agriculture, infrastructure surveillance, and crisis management. By opening up to these markets, Moroccan companies can amortize their investments, smooth cycles, and diversify revenues. In this context, the link between technological innovation and public services becomes an asset: mapping, fire prevention, network inspection, and water resource management.

Morocco’s international visibility is strengthened. Clients appreciate quality, stability, cost competitiveness, as well as logistical proximity to Europe and Africa. Cooperation with diverse partners, including Israeli, Indian, and European ones, reduces dependencies and promotes the diffusion of good practices. Specialized press notes an increase in exchanges and an intensification of technological contracts around the Mediterranean.

Dual-use applications and local value creation

Diversification towards structured civil uses relies on partnerships with infrastructure operators, mapping agencies, and agritech players. Standardization of certain platforms and modularity of payloads allow offering high value-added services, operated from the territory, in compliance with local regulations.

- 🌾 Precision agriculture: imagery, dosage, water monitoring.

- 🏗️ Infrastructure inspection: roads, bridges, power lines.

- 🔥 Civil security: forest fires, search and rescue.

- 🌊 Coastal management: erosion, port surveillance.

- 🏙️ Urbanism: updated mapping, construction site monitoring.

| Civil segment 🏢 | Benefit for Morocco 🇲🇦 | Key skill 🧠 | Impact indicator 📊 |

|---|---|---|---|

| Agritech | Yield + sustainability 🌱 | Remote sensing | Input reduction 10-20% ✅ |

| Infrastructure | Predictive maintenance 🛣️ | 3D models | Fewer major breakdowns 📉 |

| Civil security | Rapid response 🚒 | BVLOS operations | Reduced intervention time ⏱️ |

| Coastal management | Coastal protection 🌊 | Multispectral sensors | Early warnings 🛰️ |

To sustain these benefits, industrial zone development and logistics must remain priorities. Useful insight is offered on urban planning levers serving ecosystems, often underestimated but decisive to streamline supply chains and attract talents. Ultimately, the UAV sector offers Morocco a credible trajectory of moving upmarket, at the crossroads of industry, technology, and services.

The Kingdom’s positioning is thus affirmed on a winning triptych: industrial excellence, partnership openness, and territorial anchoring.

For further reading on the territorial dimension and the rooting of industrial projects, see also this resource dedicated to urban organization of production hubs, a useful complement to the UAV industrialization strategy.

{“@context”:”https://schema.org”,”@type”:”FAQPage”,”mainEntity”:[{“@type”:”Question”,”name”:”Quels emplois sont cru00e9u00e9s par lu2019usine de drones de Benslimane ?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Les cru00e9ations du2019emplois couvrent lu2019intu00e9gration avionique, les composites, la qualitu00e9, la supply chain et la maintenance HSE. Des mu00e9tiers digitaux (MES, data, cybersu00e9curitu00e9) complu00e8tent le dispositif. Les besoins vont des techniciens spu00e9cialisu00e9s aux ingu00e9nieurs mu00e9thodes et qualitu00e9.”}},{“@type”:”Question”,”name”:”Le partenariat avec lu2019entreprise israu00e9lienne implique-t-il un transfert de technologie ?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Oui. La feuille de route pru00e9voit lu2019assemblage local, puis la fabrication progressive de sous-ensembles (composites, harnais) et, u00e0 terme, le co-du00e9veloppement de charges utiles. Des formations initiales ont u00e9tu00e9 ru00e9alisu00e9es pour su00e9curiser la montu00e9e en compu00e9tence.”}},{“@type”:”Question”,”name”:”Quelles retombu00e9es pour les PME marocaines ?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Les PME positionnu00e9es sur les composites, le cu00e2blage, les traitements de surface, la logistique spu00e9cialisu00e9e et le recyclage bu00e9nu00e9ficient de nouveaux marchu00e9s. Lu2019accu00e8s impose des standards qualitu00e9 u00e9levu00e9s et une trau00e7abilitu00e9 renforcu00e9e.”}},{“@type”:”Question”,”name”:”Comment la conformitu00e9 export est-elle gu00e9ru00e9e ?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”Les flux sont ru00e9gis par des licences du2019export, des clauses du2019usage final, des contru00f4les de su00e9curitu00e9 et une trau00e7abilitu00e9 complu00e8te. Des audits ru00e9guliers attestent du respect des normes et des bonnes pratiques.”}},{“@type”:”Question”,”name”:”Quelles compu00e9tences prioriser pour u00eatre recrutu00e9 ?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”ESD et cu00e2blage, contru00f4le NDT, systu00e8mes embarquu00e9s, qualitu00e9 (SPC, AMDEC), anglais technique et outils digitaux du2019atelier (MES). Les certifications courtes amu00e9liorent lu2019employabilitu00e9 et lu2019u00e9volution de carriu00e8re.”}}]}What jobs are created by the Benslimane drone factory?

Job creations cover avionics integration, composites, quality, supply chain, and HSE maintenance. Digital trades (MES, data, cybersecurity) complement the setup. Needs range from specialized technicians to methods and quality engineers.

Does the partnership with the Israeli company involve a technology transfer?

Yes. The roadmap foresees local assembly, then progressive manufacturing of sub-assemblies (composites, harnesses), and ultimately co-development of payloads. Initial training was carried out to secure the skill upgrade.

What are the benefits for Moroccan SMEs?

SMEs positioned in composites, wiring, surface treatments, specialized logistics, and recycling benefit from new markets. Access requires high-quality standards and enhanced traceability.

How is export compliance managed?

Flows are governed by export licenses, end-use clauses, security controls, and complete traceability. Regular audits attest to compliance with standards and best practices.

Which skills should be prioritized for recruitment?

ESD and wiring, NDT control, embedded systems, quality (SPC, FMEA), technical English, and workshop digital tools (MES). Short certifications improve employability and career advancement.

Comments are closed